PDCA Loop: The Simple, Powerful System for Continuous Improvement

Sep 09, 2025

“Don’t just fix problems. Improve the system.”

That’s the mindset behind one of the most effective and overlooked frameworks in business: the PDCA Loop—Plan, Do, Check, Act.

In a world that worships fast results, this is the framework that champions small wins, steady progress, and long-term excellence.

At Myford University, we’re big believers in systems that actually help you think and improve—not just look smart in a PowerPoint. The PDCA Loop delivers, and in this deep dive, you’ll learn what it is, why it works, and how to make it part of your workflow today.

- What Is the PDCA Loop?

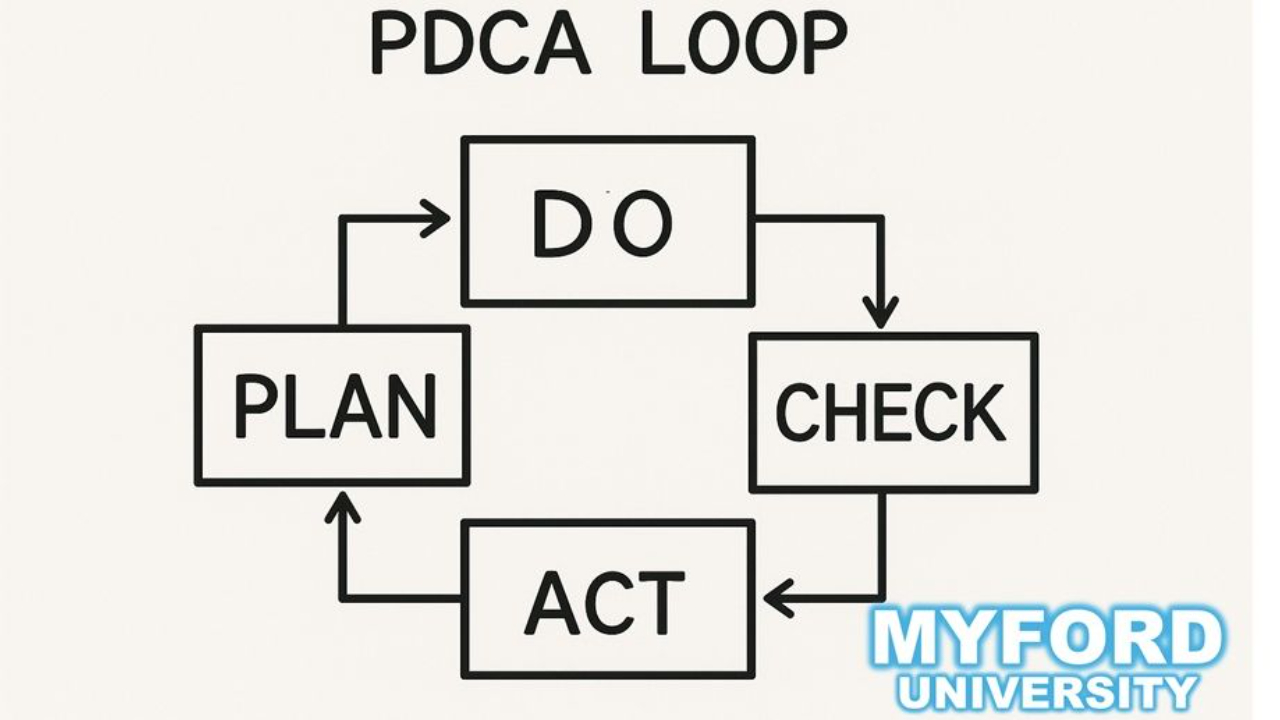

The PDCA Loop is a four-step cyclical method for problem-solving, process improvement, and performance enhancement.

The four stages are:

- Plan – Identify the issue or opportunity. Design an improvement or change.

- Do – Test the plan in a small, controlled way.

- Check – Measure the results. Did it work? Why or why not?

- Act – Standardize the success or adjust and repeat.

It’s also known as the Deming Cycle, named after Dr. W. Edwards Deming, a pioneer in quality management. Though the original idea came from his mentor Walter Shewhart, Deming popularized it worldwide—especially in Japan, where it became the backbone of Toyota’s quality system.

- Why It Matters (And Why It Works)

Too many businesses operate like this:

- Identify a problem

- Make a quick fix

- Hope it sticks

- Move on

That’s not improvement. That’s reaction.

The PDCA Loop breaks that habit. It slows you down—just enough to avoid waste, bad assumptions, and avoidable errors.

It works because:

- It forces clarity: What are we really trying to fix?

- It builds in testing: Let’s try before we scale.

- It gives you data: What actually changed?

- It encourages iteration: Learn, refine, improve.

Whether you're fixing a broken process or launching something new, PDCA is how you get smarter as you go.

- Who Should Use It?

If you:

- Solve problems

- Lead projects

- Run operations

- Manage teams

- Own a business

- Want to improve anything—

Then this loop is for you.

It’s used by:

- Manufacturers improving production

- Software teams refining product releases

- Healthcare organizations reducing errors

- Startups testing MVPs

- Educators improving lesson design

- Consultants refining client solutions

Even individuals can use it—think fitness goals, budgeting, or productivity systems.

This is a universal method for doing better work.

- When Should You Use PDCA?

Anytime you’re:

- Solving a recurring issue

- Improving a process or workflow

- Rolling out a new system

- Testing a product, campaign, or initiative

- Trying to eliminate waste, defects, or delays

- Creating a culture of continuous improvement

PDCA isn’t just for emergencies. It’s for everyday excellence—and it shines brightest when used regularly.

- Where It Fits in Business

PDCA sits at the core of any operations or quality management system.

You’ll find it in:

- Lean and Six Sigma initiatives

- Kaizen events

- Agile development cycles

- Project post-mortems

- SOP (Standard Operating Procedure) refinement

It’s a thinking loop that drives Kaizen: small, daily improvements that compound over time.

- How to Use PDCA—Step by Step

Let’s walk through each stage in detail, with real-world examples and questions you should ask at every step.

- PLAN

“What exactly are we trying to fix or improve?”

This is the most important step—and the one most people rush. It involves:

- Defining the problem or opportunity

- Setting clear objectives

- Analyzing current conditions (data, inputs, process flow)

- Brainstorming and selecting potential solutions

Key Questions:

- What’s going wrong—or could go better?

- What does success look like?

- What’s causing the issue?

- What resources and constraints are in play?

- What do we need to measure?

Example:

In a warehouse, customer orders are delayed. In the Plan phase, you investigate and find that packaging delays—not picking or inventory—are the main bottleneck.

You brainstorm solutions:

- New workflow

- Extra labor during peak times

- Improved packaging station design

You pick the most promising one and plan a small test.

- DO

“Let’s test it in a controlled way.”

This is your pilot or prototype phase. You implement the change on a small scale, so if it fails, the damage is minimal—and you can learn fast.

Key Actions:

- Run the test

- Observe carefully

- Collect initial feedback

- Keep variables as controlled as possible

Key Questions:

- Are we following the plan?

- Are there any surprises?

- What’s working or not working in real time?

Example:

You redesign one packaging station with the new layout. You train one shift. You don’t roll it out company-wide—just test the change.

- CHECK

“Did it work? And if not, why?”

You now measure results against your original plan. You’re looking for evidence—not just gut feel.

This step is often skipped or rushed. Don’t make that mistake.

Key Actions:

- Collect data from the test

- Compare actual vs expected outcomes

- Analyze why results differed (good or bad)

- Look for unintended consequences

Key Questions:

- Did we hit the target?

- What metrics improved, stayed flat, or got worse?

- Were there ripple effects we didn’t expect?

- What did we learn?

Example:

After 2 weeks, packaging time per order is down 18%. However, some team members report discomfort due to the new table height. That’s critical input before scaling.

- ACT

“Standardize the win—or adjust and try again.”

This is where you close the loop and decide what to do next.

If the test worked:

- Document it

- Train others

- Scale the change

- Update SOPs

- Celebrate the win

If it didn’t work:

- Analyze what went wrong

- Adjust your hypothesis

- Re-enter the PDCA loop with a better plan

Key Questions:

- Should we adopt this change permanently?

- What’s the best way to roll it out?

- How will we train and monitor it?

- If it failed, what will we try next?

Example:

You adjust the workstation to fix the ergonomic issue, then roll out the improved layout to all packaging areas over the next month—with training and oversight.

PDCA Is a Loop, Not a Line

This isn’t one-and-done.

The real magic of PDCA is that it builds a habit of continuous improvement.

Every time you complete a cycle, you:

- Get smarter

- Improve faster

- Build capability

- Reduce waste

- Improve morale

It’s about building an improvement engine—not a suggestion box.

Example Use Cases

Let’s bring this to life with a few fast examples.

Manufacturing (Lean Six Sigma)

Problem: Too many defects in assembly line

Plan: Analyze root causes, test new inspection step

Do: Add visual quality check to one station

Check: Defect rate drops by 30%

Act: Train rest of line and document process change

Software Development (Agile)

Problem: Too many bugs after releases

Plan: Add automated testing stage to CI/CD pipeline

Do: Implement test for one module

Check: Bug reports decrease

Act: Expand to all modules

HR & People Ops

Problem: New hires are quitting during onboarding

Plan: Redesign onboarding with peer mentorship

Do: Test with 5 new hires this quarter

Check: Retention improves by 40%

Act: Roll out company-wide and create training for mentors

Why PDCA Is a Power Tool

Here’s why we teach it so hard at Myford:

- It’s cheap. Doesn’t need software or consultants.

- It’s fast. You can run a cycle in a few days.

- It builds momentum. Small wins become big wins.

- It empowers teams. Everyone can participate in improvement.

- It works anywhere. Any industry, any team, any size.

And most importantly:

It teaches you to think in systems.

It forces learning from reality—not assumptions.

It makes continuous improvement your culture, not just a buzzword.

Final Thoughts: Don’t Just Work—Improve

The PDCA Loop won’t win you awards.

It’s not flashy.

It doesn’t require fancy tools.

But it might be the single most powerful process improvement tool you’ll ever use—because it’s simple, repeatable, and focused on learning.

So if you’re stuck with:

- Firefighting mode

- Stalled projects

- Inefficient processes

- Low team morale

- No improvement culture

Start with Plan–Do–Check–Act.

It’s small. It’s quiet. But it gets the job done.

Over time? It builds organizations that think, adapt, and outperform.

Stay connected with news and updates!

Join our mailing list to receive the latest news and updates from our team.

Don't worry, your information will not be shared.

We hate SPAM. We will never sell your information, for any reason.